Tools, molds and die fabrication for plastic thermoforming

Leveraging our experience and nearly two dozen CNC machine tools and the latest in CAD/CAM software, our tooling is built to meet your production requirements and last for the long haul. We also provide ongoing maintenance and mold and die refurbishment for your existing tooling.

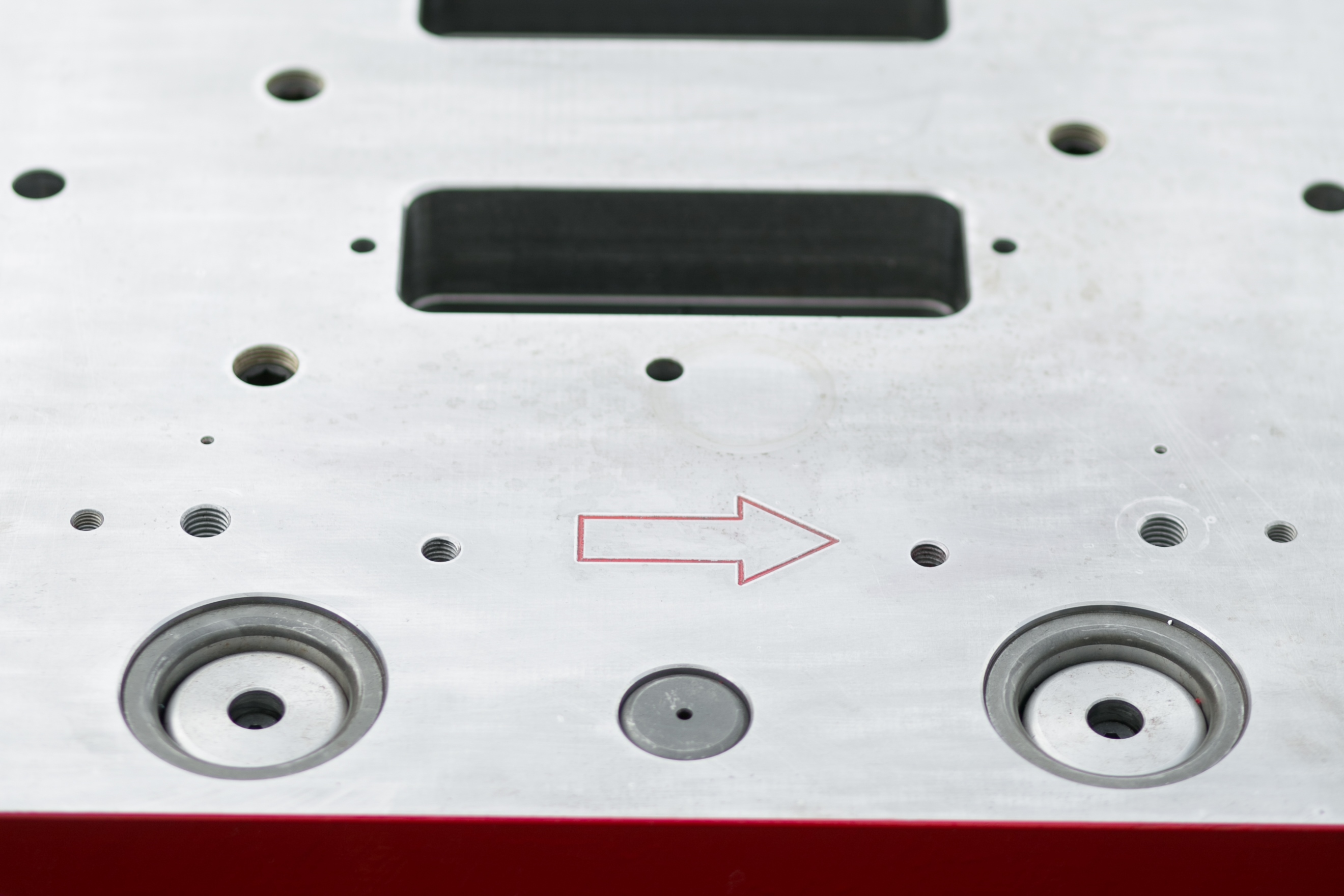

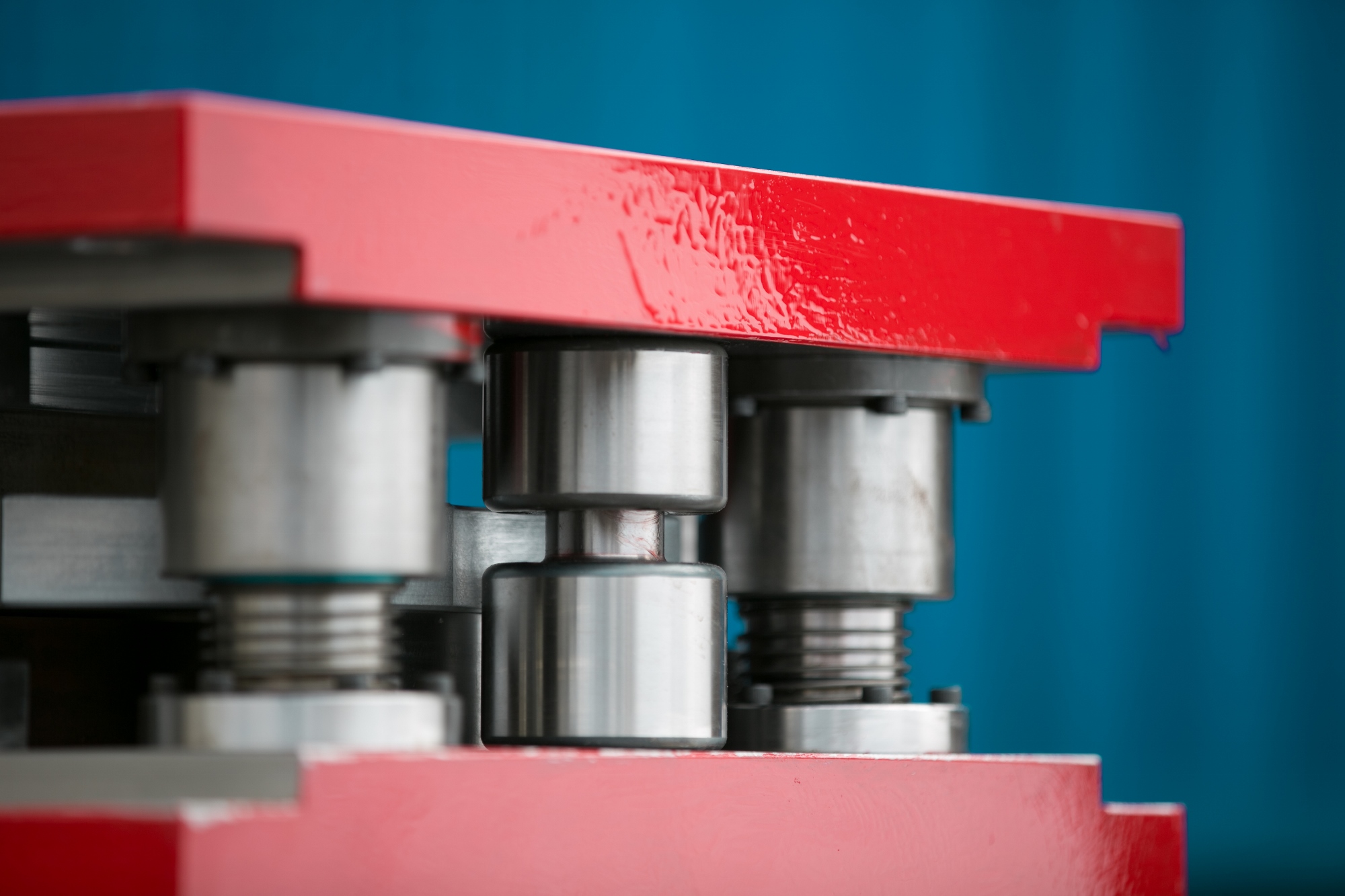

Trim tooling

Starting with properly hardened and ground punches and dies, our match metal trim tools maintain close punch to die tolerances to achieve clean, trimmed edges for perimeter, hole and slot punching, side wall pre-punch, and scoring applications.

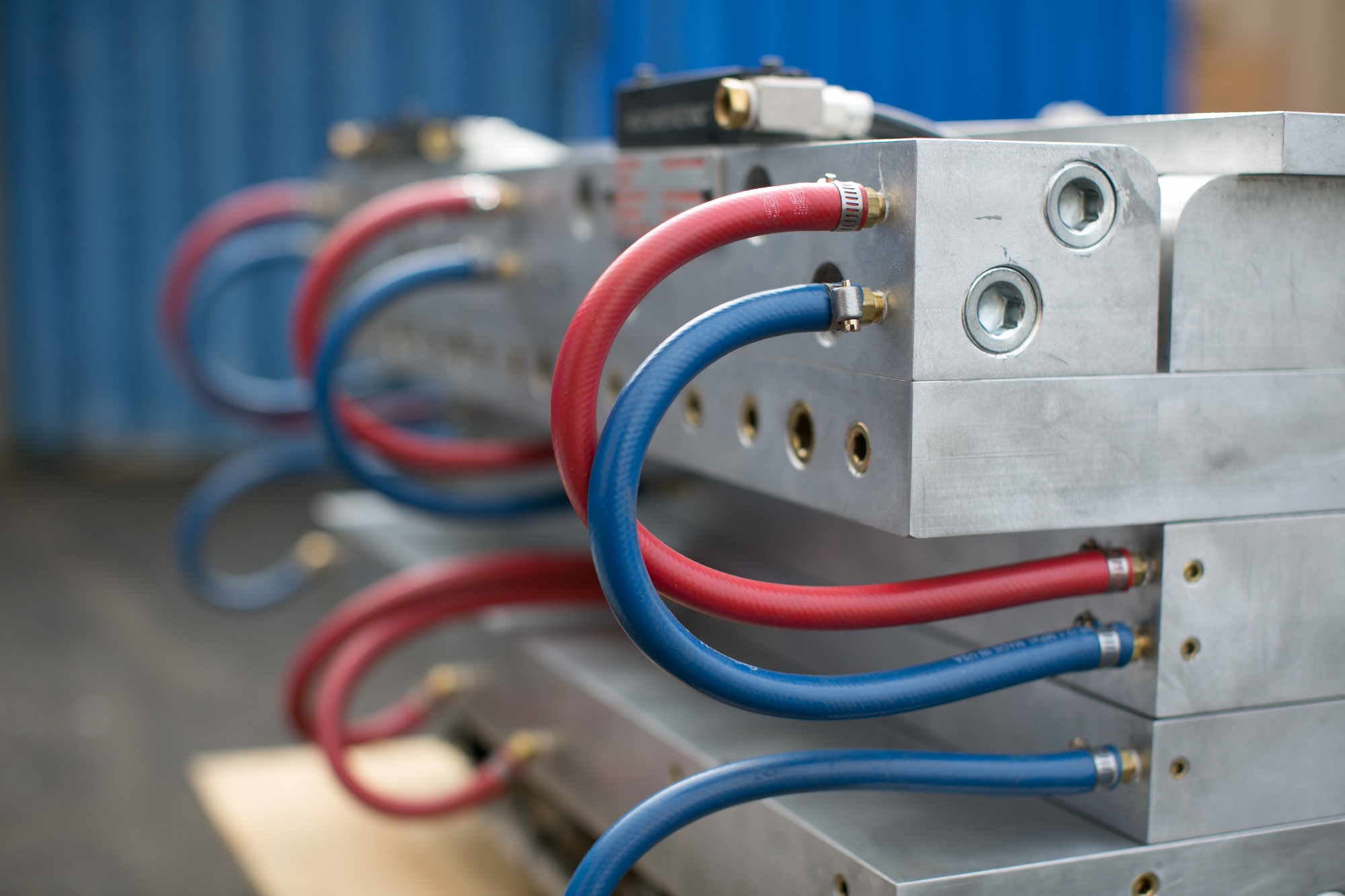

Form tooling

High cavitation aluminum molds, coupled with the latest in plug assist technology, deliver a high performance cycle time for PET, PP, HIPS, and other plastics utilized in inline roll-fed pressure forming applications. Conforming to all major thermoforming platforms, we specialize in wide-bed solutions.